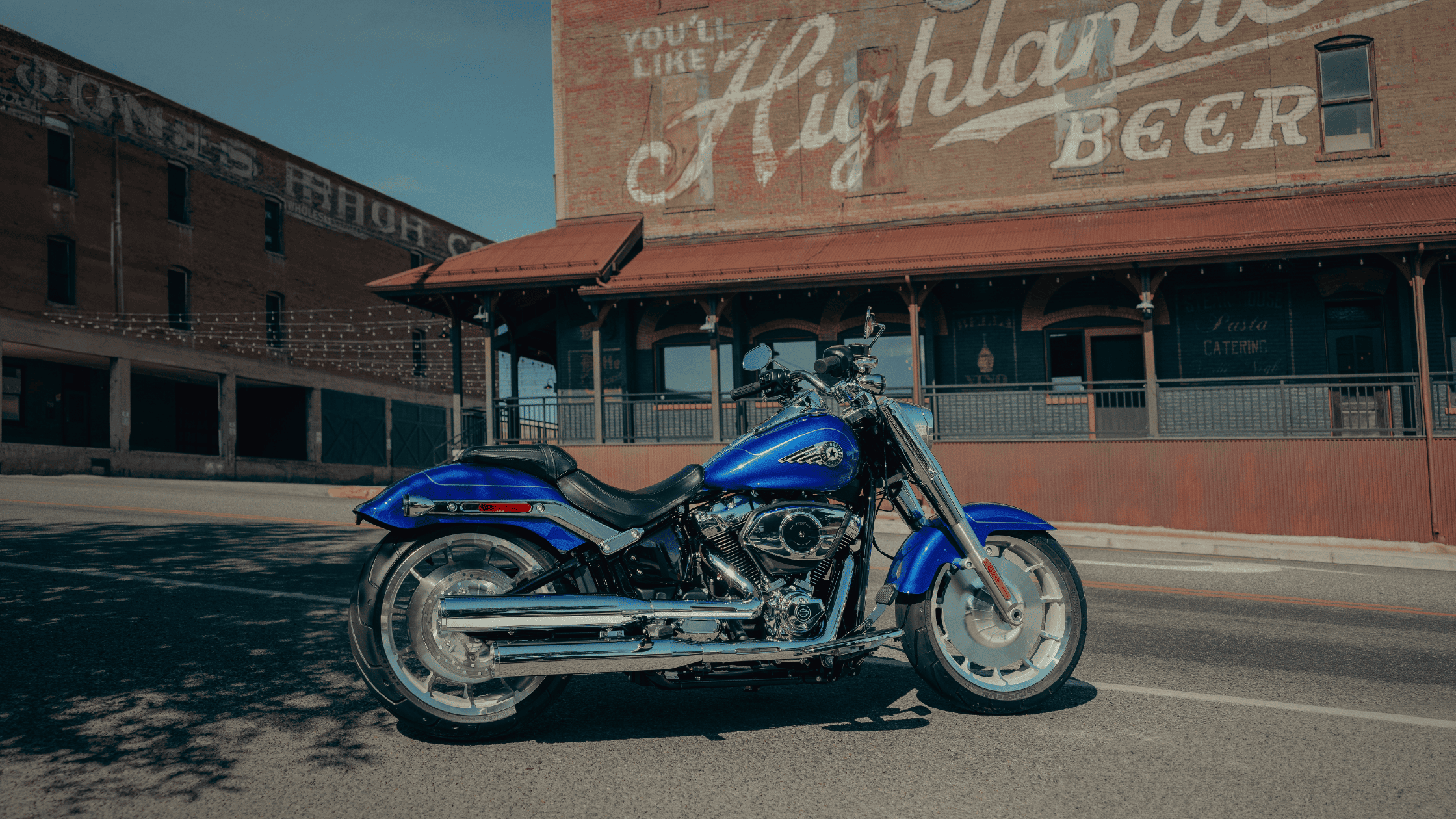

2025 Harley-Davidson® Fat Boy® in Augusta, GA

The 2025 Harley-Davidson® Fat Boy® continues as a consistent entry in the Cruiser category, known for its distinctive proportions, rigid Softail® frame, and Milwaukee-Eight® 117 Custom engine. With solid-disc wheels, a low-slung chassis, and a wide rear tire, the 2025 Harley-Davidson® Fat Boy® stands out through function-first design and consistent road performance. The model maintains its signature appearance while refining mechanical components to support comfort and control. The design is cohesive and clean, intended for long-haul riders who prioritize torque, durability, and predictable geometry over unnecessary complexity.

Powertrain: Milwaukee-Eight® 117 Custom Engine Performance

The Milwaukee-Eight® 117 Custom V-Twin powers the 2025 Harley-Davidson® Fat Boy®. This engine displaces 117 cubic inches and is both oil- and air-cooled. The torque output measures 126 lb-ft at 3,000 RPM. The engine is designed to support steady roll-on power, with a focus on delivering usable torque throughout the rev range. The throttle response is crisp due to the design of the intake and combustion systems. The engine’s compression ratio is 10.5:1, and bore and stroke measure 4.075 inches and 4.5 inches, respectively.

An electronic sequential port fuel injection system regulates fuel delivery, and a six-speed transmission transfers power to the rear wheel through a belt final drive. The gear ratios support consistent acceleration across varying conditions. The exhaust system is finished in bright chrome and features dual mufflers that contribute to backpressure control while offering a signature Harley-Davidson® rumble.

Chassis: Softail® Frame Structure

The 2025 Harley-Davidson® Fat Boy® uses the Softail® platform. This frame design balances stiffness and weight to deliver a more direct response from rider input to road output. The frame mimics the visual design of a hardtail but includes a concealed rear mono-shock suspension system. This suspension allows for rider-adjustable preload tuning, which improves adaptability for different road conditions or load requirements.

The swingarm and rear shock design ensure structural rigidity without affecting comfort. The model includes a 49mm dual-bending valve telescopic fork at the front. The rake measures 30 degrees with a trail of 4.1 inches, contributing to balanced handling geometry.

Dimensions: Length, Weight, and Contact

The 2025 Harley-Davidson® Fat Boy® has an overall length of 93.1 inches and a wheelbase of 65 inches. Ground clearance measures 4.9 inches, while seat height is set at 25.9 inches laden. This combination contributes to a low center of gravity.

The front tire is 160mm in width, mounted on an 18-inch wheel. The rear tire is significantly wider at 240 mm and is also mounted on an 18-inch wheel. Both wheels feature Lakester solid-disc designs, finished in chrome. The model’s running order weight is 694 pounds. The fuel tank holds five gallons, and estimated fuel economy is rated at 47 mpg.

Lighting and Visibility

The 2025 Harley-Davidson® Fat Boy® uses LED lighting systems across the headlamp, rear light, and indicators. The LED headlamp is mounted in a chrome nacelle and provides consistent forward illumination for night riding and increased visibility during daytime operation. The lighting is engineered to meet visibility standards without obstructing the model’s design. The rear lighting includes integrated stop and turn indicators, which maintain clarity in all light conditions.

Braking System and Control Features

The braking system includes a 4-piston fixed front caliper and a 2-piston floating rear caliper. Both calipers operate single disc rotors. Anti-lock braking (ABS) is standard, helping reduce the risk of wheel lock during sudden stops. The brake system is tuned to support the weight and momentum of the motorcycle across various terrains. The wide tires also contribute to braking efficiency by distributing pressure more evenly across the contact surface.

The handlebar-mounted control system includes a compact digital instrument cluster. This unit displays speed, gear selection, trip information, fuel level, and range estimates. The display is integrated into the handlebar riser, keeping the dash compact while ensuring visibility under direct sunlight. The controls are positioned for quick access and are consistent with other models in the Cruiser segment.

Ergonomics and Rider Interface

The seating arrangement is designed to provide comfort over extended periods. The seat is contoured and positioned to allow flat-foot contact at stops. The wide handlebar supports an upright riding posture, while the forward-mounted foot controls promote a relaxed leg position. The ergonomic triangle, defined by handlebar reach, seat height, and footpeg position, is tuned for long-distance riding without unnecessary strain.

The seat is engineered with foam density that resists compression over time. The wide surface area distributes rider weight evenly. Vibration is reduced through both engine balancing and the isolating properties of the rear suspension system.

Material Finishes and Structural Details

Chrome finishes dominate the engine covers, exhaust pipes, forks, and handlebar components. This high-gloss application is designed for durability and corrosion resistance. The fuel tank features a centered console and maintains a clean, symmetrical surface free from unnecessary contours or overlays.

Fenders are made from stamped metal with clean edge lines and are painted to match the fuel tank. Color options vary by model year, and the paint system used is engineered for UV and wear resistance.

Technology Integration and Electrical Systems

The model features a keyless ignition system controlled through a proximity-based security fob. The system activates the electrical circuits when the fob is within range, removing the need for a physical key. The electrical system also supports self-canceling turn signals, LED indicator functionality, and a diagnostics-ready ECU that allows for dealer-based service tracking.

The wiring harness is routed internally where possible to preserve the clean lines of the chassis and minimize points of failure. Electrical connectors are sealed to protect against moisture and dust, supporting consistent system performance in varying weather conditions.